Completely Wireless Plastic

Although plastic swords are available from a number of distributors, the majority fall into one of the following categories:

Non-electric - bare sword with rubber boot at the tip.

Acoustic electric - a switch at the tip connects to a buzzer and battery in the handle. The buzzer sounds whenever the tip is pressed. The switch at the tip is covered with a rubber boot.

Wired electric - a switch is mounted on a PCB which fits inside the handle. A traditional body wire is permanently hardwired to the PCB and comes out the end of the handle. The switch on the PCB connects to a small plastic ball in the tip via plastic push rods in the hollow blade. The switch at the tip is covered with a rubber boot.

The switches used on the acoustic electric and wired electric swords are not designed to survive the harsh environment of fencing, particularly hits to a hard floor. High impact forces either damage the switch button or shatter the case of the switch. Even with normal hits to the body, these switches have a limited number of operating cycles, typically between 10K to 50K, which is only a year of typical fencing.

The rubber boot fitted to all existing plastic swords covers the end of the barrel and has a limited amount of movement. They can easily tear, which is why they need replacing. I can only assume they were originally intended to reduce the impact force for the fencer being hit. In reality, once the rubber boot has compressed under impact, the forces are the same whether the boot is made from rubber or a hard plastic.

My objective was to produce the first robust and reliable wireless electric plastic sword that would look, feel and function the same as a metal sword, allowing fencers to easily transition from plastic swords to metal swords.

My approach was to add a new tip switch to an existing plastic sword that would combine the functionality of a metal epee tip switch, whilst removing the need for a rubber boot and reducing the impact forces.

An exploded view of the tip switch is shown below.

Blade wire - this is a standard epee blade wire which has a plastic housing at one end with two small metal pads. The two wires run down the inside of the blade down to the handle.

Spacer - this plastic ring positions the housing in the centre of the barrel and holds it in place.

Pressure spring - this larger spring provides resistance when the tip is pressed. It has been carefully selected to provide enough resistance to feel similar to a metal epee.

Contact spring - this smaller spring is screwed inside the tip and connects the two pads in the housing together when the tip is pressed.

Tip - this is made from hard durable plastic and fits over the barrel. The tip is 20mm in diameter and has a surface area of 628mm2. This is significantly more than the 12mm diameter and 226mm2 for the rubber boot.

Screws - the tip is secured onto the barrel with two screws, which function the same as grub screws on a metal epee.

The CWF tip switch has been tested for 250K+ hits to body and 500+ hits to a hard floor without any degradation in performance or damage. This is equivalent to more than five years of average use.

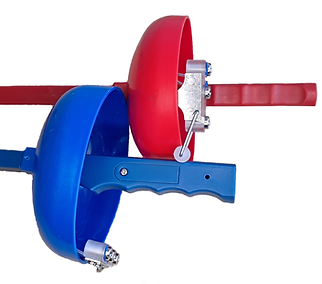

At the handle end of the sword we offer two wireless options, socketed and integrated:

Socketed - a standard epee socket is fitted to the handle. When combined with the CWE Plugin you have full wireless system. It can however, be used with existing body wires, spools and scoring boxes.

Integrated - a small PCB is fitted inside the handle, which contains the wireless electronics. When combined with the CWE Repeater Relay you have full wireless system. Available with epee or foil guards.